How To Install A Mezzanine Floor

Mezzanine

Introduction

This article takes an in depth await at mezzanines.

Y'all will learn:

- What is a Mezzanine?

- What are Mezzanines used for?

- How to Install a Mezzanine

- Important Facts well-nigh Mezzanines

- Building Codes Regarding Mezzanines

- And much more…

Chapter 1 – What is a Mezzanine?

A mezzanine is an intermediate flooring installed in a edifice between the chief flooring and the ceiling that is partly open to the principal floor. They have a low ceiling and project out over the main floor just do not completely cover information technology. Mezzanines tin be freestanding, hung from the ceiling, or be a permanent part of a building.

In many instances, mezzanines are referred to as the flooring above the ground flooring. Depending on their purpose, mezzanines can exist permanent or temporary and serve every bit extra part infinite, storage area, or a work platform. Mezzanines tin can be installed in multiple locations and formats from a platform outside a building to ameliorate building access or as a second level to a work expanse.

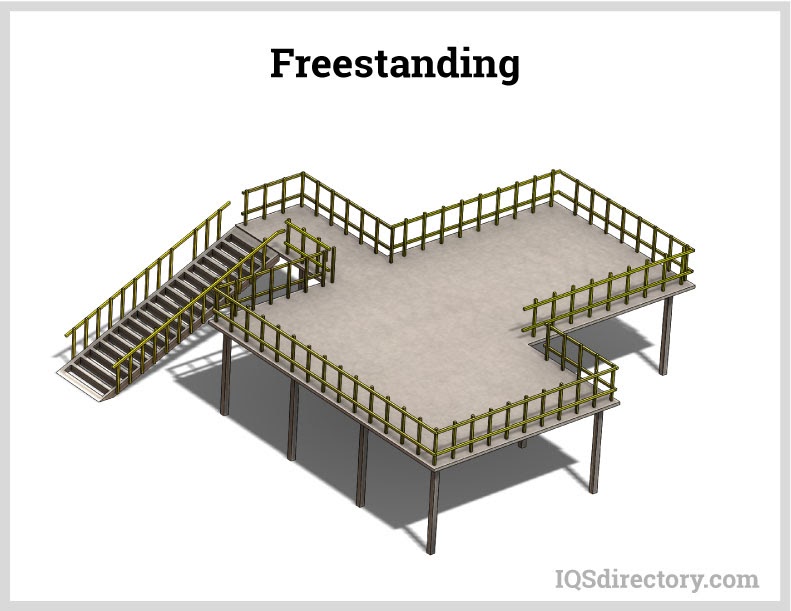

Freestanding mezzanines, as seen in the diagram below, can easily exist dismantled to exist repositioned or relocated.

Unfortunately, apply of the term mezzanine tends to create confusion since buildings are built with permanent mezzanine levels, are made of concrete and steel, and are included in a building inspector's classification of a edifice.

A mezzanine deck or piece of work platform is not a permanent structure and is normally added after a building has been completed. Mezzanine decks are additional workspaces that are added as a company expands its functioning and grows. They get a necessity when there is a need for extra space.

An piece of cake style to separate mezzanines is to determine their classification. In the case of a structure that is included in the original construction of a building, it appears on a edifice inspector's written report and is regularly checked. They crave facilities such as bathrooms, handicap accessibility, and elevators and are included in the taxation assessment of the building.

The other grade of mezzanine, the less permanent variety, is a piece of equipment similar to production machines and diverse types of mechanism. They appear on an inspector'south study as equipment.

Though mezzanines are temporary, they are solidly built from cold rolled steel, hot rolled steel, stainless steel, fiberglass, or aluminum. Decking or floor can be finished forest, steel, aluminum, or fiberglass grating.

Mezzanines are usually installed in companies that are expanding and require additional infinite for storage, offices, or work areas. They are a toll effective method for maximizing used infinite and doubling a edifice'southward available work expanse.

Typically, mezzanines are installed in warehouses, distribution centers, and factories with high ceilings to take reward of the unused space below the ceiling. Industrial mezzanines are structural, roll formed, rack-supported, or shelf-supported with room for high density storage.

Chapter Two – Types of Mezzanines

When making the decision to install a mezzanine, the offset consideration is the load requirement. Though all mezzanines have like design, the type of materials to construct them vary depending on the amount of weight they will have to support. Aluminum or fiberglass can be perfect for boosted offices or lite part storage. In the case of heavy equipment, steel or stainless steel would be the better selection.

Types of Mezzanines

Freestanding Mezzanines

Free standing mezzanines, or equipment platforms, are not connected to the primary structure of the building and are flexible enough to be reconfigured. They take a securely fixed base that is completely safety but easy to move or reposition. Supported by columns, free-standing mezzanines are bolted to the floor and take up minimal infinite. They are perfect for situations where the infinite nether the mezzanine needs to be used.

Shelving and Rack Supported

Rack supported mezzanines are lighter and offer the option of a catwalk with a storage area. They are a toll effective method of providing extra storage space. Rack supported mezzanines are supported by rack uprights instead of structural legs. The framing of the mezzanine, joints and stringers, bolt to columns to create the decking. The connectedness to the columns makes the decking more than stable and firmly anchored. Racks and shelves are close together to support the structure.

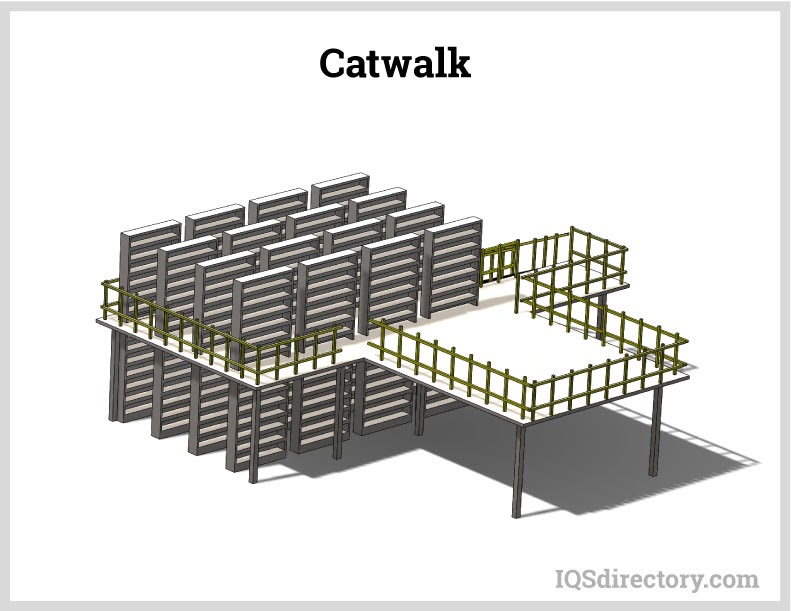

Catwalk Mezzanines

Catwalk mezzanines are used to increase the capacity of tall shelves or racks. The upper surface area of arack is attainable from catwalks that extend from the floor of the mezzanine. Existing shelving provides support for the mezzanine frame. Support columns tin exist added to offering boosted support between the shelves. Catwalk mezzanines are a variety of shelving and rack supported mezzanines.

The principle and main employ of catwalks are equally walkways for access to conveying systems, mechanism, hoppers, silos, and cranium space. Much similar mezzanines, catwalks accept advantage of overhead space by transforming it into secure and safe walkways for a multitude of purposes. They can be self supporting like a freestanding mezzanine or hung from ceiling drops.

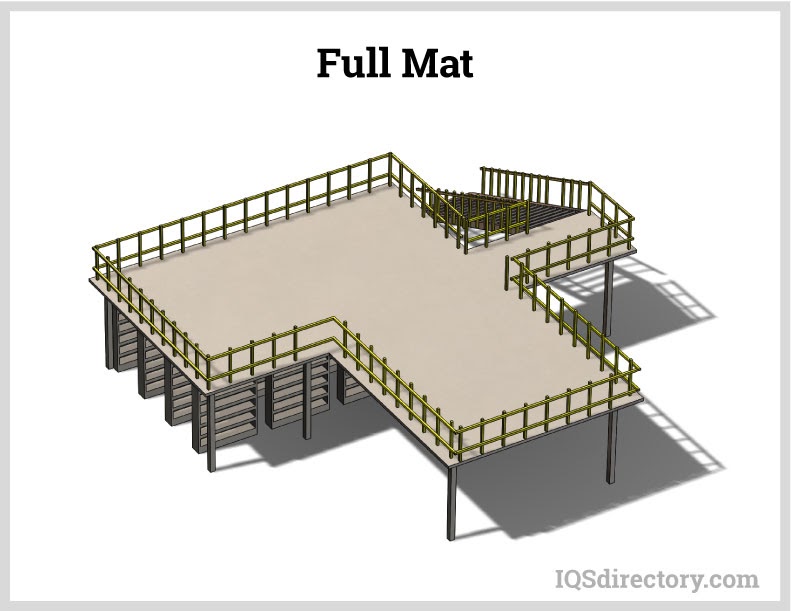

Full Mat

Full mat mezzanines are another variety of shelves and rack supported mezzanines. They combine the features of free-continuing and catwalk designs and are supported past shelving or rack uprights. As tin be seen in the diagram, the surface area to a higher place the shelving is open and tin exist used for majority storage, office infinite, or an employee cafeteria. They can be installed over existing shelving or rack uprights.

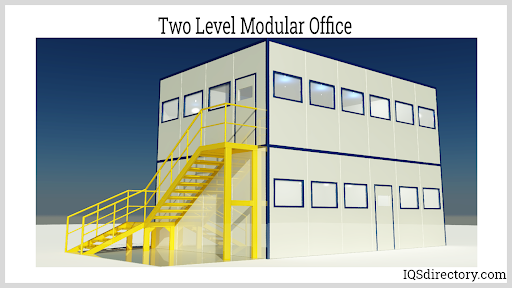

Prefabricated

Prefabricated, or modular, mezzanines come up ready for use and are handy for speedily added extra space. They are free-standing and delivered ready to install to fit seamlessly into a work space. Prefabricated mezzanines are engineered for piece of cake associates and can be reconfigured when circumstances alter.

Common uses for prefabricated mezzanines include storage, offices, towers, and equipment platforms. Their easy installation increases floor pace chop-chop and economically. They are less expensive than constructed mezzanines and take less time and labor to gear up. Every bit with custom designed mezzanines, prefabricated mezzanines come in assorted heights, number of platforms, weight capacities, and beam and cavalcade configurations.

Scroll Formed Mezzanines

Curl formed mezzanines are an economical cost effective storage solution that can add extra space using low-cal gauge steel. They are designed for commercial warehousing, retail stores, or any location where at that place is limited interaction of the mezzanine with forklifts or heavy lifting equipment. Rolled course mezzanines tin can exist installed quickly in a wide variety of sizes to fit the needs of an performance. Their light weight makes it possible to adapt them to fit workload changes.

Structural Steel Mezzanines

A structural steel mezzanine has steel beams and columns with metal decking for concrete or woods applications. Unlike curlicue formed mezzanines, structural steel mezzanines are heavier and a better selection for shops and businesses that accept large expansive production areas. They are fabricated from loftier form heavy duty steel that is durable enough for equipment handling and warehousing machinery.

Steel made mezzanines are found in warehouses, equipment platforms, and industrial and manufacturing operations. The utilize of steel provides increased immovability, strength, and safety. They tin can be freestanding and are bolted together to heighten their resilience. Concrete flooring is usually used with structural steel mezzanines for its loftier point load and low noise.

GET YOUR COMPANY LISTED BELOW

Leading Manufacturers and Suppliers

Chapter Three – Uses for Mezzanines

In the majority of cases, mezzanines are used for extra storage infinite and to take advantage of the unused area under the ceiling. Though this may be a main use, manufacturers have expanded the bachelor types of mezzanines to fit a wider array of uses.

In addition to extra storage infinite, mezzanines provide a work expanse for equipment or machinery in hard to reach areas. Chemic tanks, industrial pumps, sorting machines, conveyor systems, and space capsules are the types of equipment that mezzanine systems tin be designed to suit. The adjustable deck heights, load ratings, and deck layouts allow for piece of cake access to automobile maintenance and specialized processes. Described beneath are a few of the uses for mezzanines.

Role Infinite:

Mezzanine offices are a comfortable work environs above the floor simply accept upwards a minimal workspace. In most organizations, supervisors have to remain on the manufacturing flooring only demand to have an role to complete paperwork. Mezzanine offices offer office infinite on the manufacturing plant floor not far from the piece of work area.

Catwalks:

Mezzanines tin can be designed for conveyor and catwalk systems, which offers a method for transporting employees and inventory above the facility floor in order to non disturb piece of work areas. Catwalks can exist added to connect pre-existing mezzanine levels and can be ceiling hung or supported from the flooring or adjacent structures including racks and mezzanines. The surface of a catwalk can be grated steel or solid, depending on the demand and environs. They let access betwixt buildings over machinery and equipment.

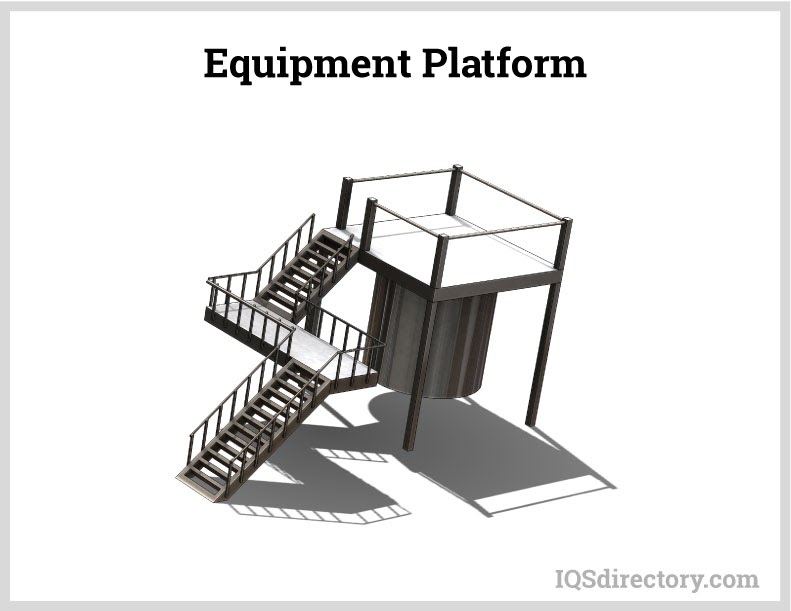

Equipment or Work Platforms:

Equipment and work platforms added extra space for heavy equipment. The area of an equipment platform can cover upward to two thirds of the main floor infinite. If a building has a mezzanine and equipment platform, the mezzanine and equipment platform will embrace two-thirds of the principal floor space and will require a sprinkling system. Work platforms tin can concord cranes, conveyors, cloth lifts, and pallet racks.

Equipment or work platforms provide support for industrial equipment and systems like piping and are supported past structural steel. They take ladders, railings and handrails, kick plates, staircases, and gates. Dissimilar regular mezzanines, equipment platforms must be designed for the amount of weight they will hold as well as their summit and other dimensions.

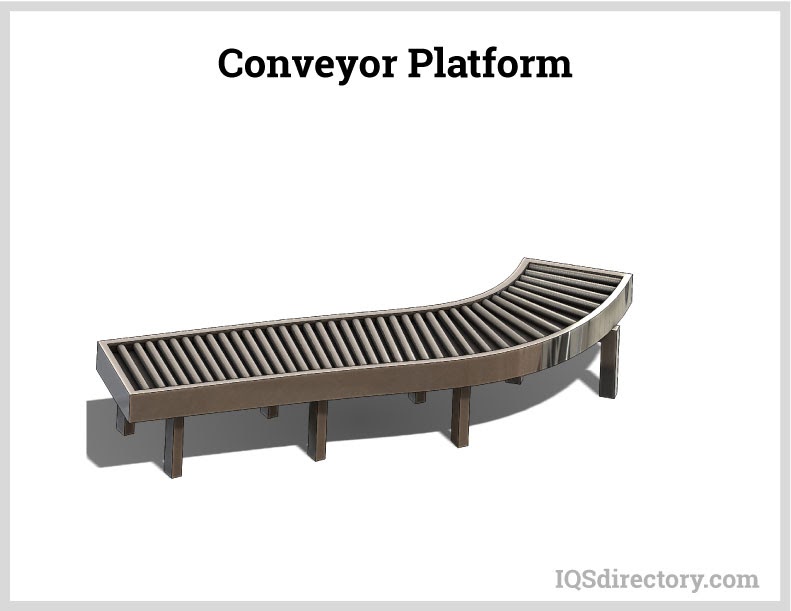

Conveyor Platforms:

Companies strive to incorporate automation into their operations merely do not take the necessary space. Overhead steel platforms, as seen in the example below, are designed to efficiently move materials leaving the ground floor free for fourth dimension sensitive and operationally critical processes.

Additional Retail Infinite:

Mezzanine floor is common in retailing since information technology adds additional display areas for products. The apply of mezzanines significantly increases per square foot space and improves shelf space. Having additional expanse in a retail space has been constitute to increase sales and profits with a small investment. The fact that a mezzanine can be torn down and relocated or removed when non needed farther enhances its value.

Workshop:

Workshops are constantly running into atmospheric condition where they have large orders but not enough infinite to encounter the demand. Mezzanines offer the flexibility to meet increased needs without having to relocate or rent an additional site. Shop congestion and overflow can be moved to a mezzanine to enhance efficiency and improve productivity. The cost of mezzanines is within the range of pocket-sized workshops that have a sudden increase in business. This aspect of mezzanines and their flexibility brand them ideal for small-scale operations to meet the requests for big orders.

Equipment Platforms

The purposes of equipment platforms are efficiency, convenience, and immediate access. Much like catwalks, equipment platforms offering articulate and unobstructed admission to equipment for monitoring, repair, and performance. They can be designed to encapsulate a slice of equipment or stand up next to it. They are freestanding made of either roll formed metals or structural steel. Aside from their use with equipment, equipment platforms can be used in facilities that take tank and silo storage for regulating and managing capacities and structure.

Chapter Four – Mezzanine Safety Measures

Mezzanines offer a cost effective style to increment the use of available infinite and take advantage of unused areas below the ceiling. As companies grow and demand boosted function and work space, but want to avoid the expense of an addition, they turn to mezzanines and platforms.

When examining the advantages of mezzanines, information technology is important to be aware of the potential safety hazards. Improper installation and employ can event in serious injuries to employees and equipment. Below is a brief description of things to consider when installing a mezzanine.

As with any construction, mezzanines have a ready of building codes and requirements that have to be followed. In most cases, each land has a separate set of codes and specifications as well as codes from the Office of Safety and Health Assistants (OSHA) and International Building Codes (IBC).

All mezzanine suppliers and manufacturers strictly adhere to the code requirements for the safety of their customers.

Safety Considerations for Mezzanines

Open Access

Much like fire exits to a building, staircases to mezzanines must never be blocked or cluttered. Obstructed admission may cause workers carrying equipment to autumn or be injured. Employees must exist properly trained on how to utilize the mezzanine and identify its risks. As a safe precaution, stair widths are required to be 36″ broad and accept skid-resistant diamond plated treads.

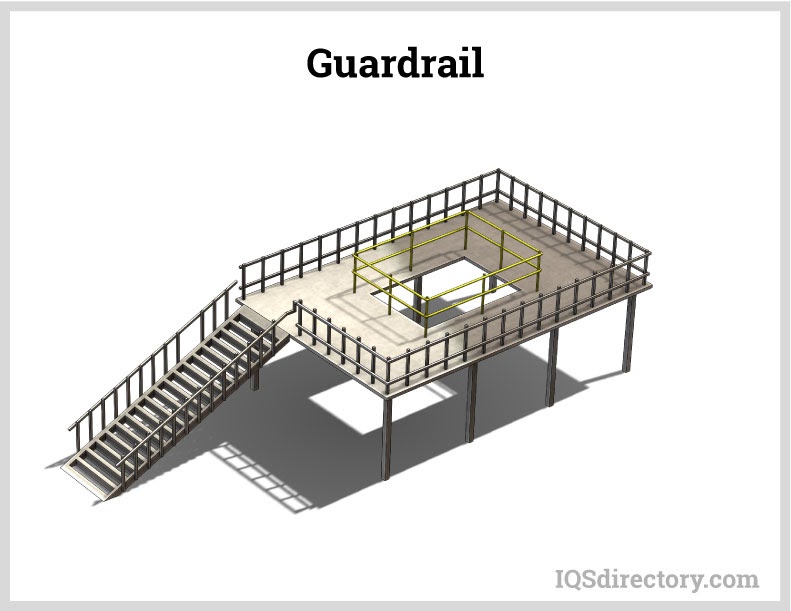

Baby-sit Rails

All mezzanines accept their own pattern specifications. In cases where a side is exposed, appropriate guardrails are required to be installed.

Load Limits

The floor of a building has to exist able to support the weight of the mezzanine. Most buildings have a floor slab that is half dozen to eight inches thick, which is capable of supporting 25,000 lbs. If the building is on sandy soil or where there is a high water table, it may not be able to support a mezzanine.

There isn't a standard load chapters for mezzanines. How much a mezzanine tin handle and its load limit is determined by local building codes and manufacturer specifications. For a mezzanine to see weight limit specification, it has to be able to back up its capacity across the entire deck area.

When calculating the amount of weight that will be placed on an installed mezzanine, the factors to consider are equipment, whatsoever office infinite, and the number of people and their weights.

Hazard Codes

Local and federal building codes apply to mezzanines. During the installation procedure, manufacturers conscientiously work to comply with all rulings and regulations. Manufacturers supply posters and notices to be displayed in the work area to make employees aware of mezzanine rules. Failure to comply with codes and regulations can lead to fines and the shutdown of the facility.

Location

A mezzanine should exist placed as close as possible to the work area that it serves to reduce the time needed for workers to access the mezzanine and avoid having to walk back and forth beyond the facility. Future growth and expansion must exist considered if it is necessary to motion the mezzanine or accept it enlarged.

Select the Correct Safety Gate

Openings in guard rails on a mezzanine create fall hazards. These are best protected past safety gates with a dual-gate organization. Tri-sided gates accept ii gates. The starting time gate is opened to allow the load to be dropped while the second gate keeps the employee back and protects them.

Material and equipment used on a mezzanine, and pallet drop surface area, help determine which blazon of safety gate model is appropriate. When overhead hoists are used about the mezzanine, a gate with an open top is appropriate. Products tin exist lifted onto the deck in the open up infinite, while the employee is protected backside a gate.

The number of gates and how they are used determines the types of gates that volition demand to be installed be needed. When overhead hoists are used most the mezzanine, a gate with an open top is advisable. Products tin be lifted onto the deck in the open space, while the employee is protected behind a gate.

There are a number of safety gate models that provide fall protection nad include roly, pivot, clear aisle, and self closing. The type of gate has to meet the use of the mezzanine and protect employees.

Pictured beneath is an open top safety gate.

Chapter Five – Installation of a Mezzanine

There are several things that need to exist considered when deciding to install a mezzanine. The near important factor is to determine how the mezzanine will be used, whether it is going to be for role space, storage, manufacturing, or equipment placement. The information beneath lists some of the factors to consider as you programme for a mezzanine installation.

Purpose:

The size and use of the mezzanine is the most critical gene, which volition determine the needed weight chapters of the mezzanine. In the majority of cases, mezzanines are congenital to increment available space.

Office of deciding on the purpose of a mezzanine is what the size of its size will exist. The size and flooring plan of a mezzanine is often determined by the bachelor infinite. In one case a articulate motion picture of the purpose has been adult, then it is necessary to design a floor plan and decide on the placement of personnel, walls, and equipment.

Goal:

Once the mezzanine is installed, it is important to empathize how it will help your functioning and improve efficiency. The goals for the mezzanine volition help make up one's mind if it will be necessary to add together additional components such as hoists, racking, or shelving.

Loading chapters:

The weight loading of a mezzanine floor is measured in kilonewtons per square meter (kN/m2). How you want to utilize the extra space will make up one's mind the necessary weight loading. The general guidelines for weight loading are:

- Office space – 3.5kN/m2

- Lite Storage – 4.eight kN/m2

- Medium Storage – 7.two kN/m2

- Heavy Storage – ix.6 kN/m2

Slab capacity:

Nearly building slabs are half-dozen to viii inches thick and capable of supporting 25,000 lbs. Prior to deciding on the type of mezzanine, engineers will carefully study the composition of the soil on which the building rests to ensure a safe installation of the mezzanine. The slab capacity determines the types of columns and footings that will be necessary to support the mezzanine.

Underneath:

OSHA requires that mezzanines be at least vii feet off the floor with enough clears for a person. When designing a mezzanine, it is important to consider how the extra space will be used.

Stairways and Handrails:

These are two major rubber considerations and are part of the purpose of the mezzanine. If the mezzanine is going to exist function of the manufacturing process, the types of handrails or guardrails volition be determined in regard to the safe of employees. The types of stairways are specified in edifice codes and are required to have handrails with diamond patterned steps as seen in the image below.

Surface:

Mezzanine floors are blended engineered wood, plywood, particle board, steel, grating, diamond plate, or physical.

- Composite engineered wood, plywood and particle board are the most economic and come up finished from the factory or can be painted.

- Steel and grating are an platonic choice when low-cal and airflow are important factors.

- Diamond Plate is an expensive selection simply is ideal for heavy signal loads.

- Concrete is a permanent solution. It offers noise reduction and is able to hold heavy loads. The use of concrete limits the flexibility of a mezzanine since the removal of a concrete floor is labor intensive and costly. Additionally, the installation of a concrete floor can take three to five days for the concrete to set.

- Wood resin composite is a long lasting flooring material able to hold upward to the abuse of pallet jacks, carts, dollies, and heavy traffic. It comes in one-half inch to one inch thicknesses and outperforms other woods like materials regardless of the atmospheric conditions. It can be worked much similar wood and can exist cutting to fit the dimensions of a mezzanine'southward floor.

Codes:

The mezzanine pattern has to see all building lawmaking requirements. This is a primary business for West Declension states like California, Oregon, Washington, Utah, and Nevada that have Seismic Zone requirements. A properly designed mezzanine meets IBC codes, AISC & ASTM standards, and OSHA requirements. International Edifice Codes (IBC) governs most parts of the United states. All mezzanine jobs are subject area to IBC requirements.

In certain cases, customers may be required to use OSHA lawmaking ASA minimum requirement for stairs and railings.

Pattern:

A well-engineered and designed mezzanine has accounted for all of the necessary variables to install a mezzanine that matches the space requirements and qualification. An over designed mezzanine will have likewise many features and use unnecessary or inappropriate materials. An nether-designed mezzanine can have the potential of structural failure and may collapse. A properly designed mezzanine uses equally lilliputian steel as possible to attain the correct capacity. A design should maximize fabric efficiency to optimize strength and have the to the lowest degree amount of textile to reach desired capacity.

Chapter Half dozen – Design & Selection Considerations

All mezzanines have the same bones elements. How they are configured and installed varies depending on the use of the mezzanine. When because the purchase of a mezzanine, information technology is important to know the basic requirements to be able to intelligently discuss the installation with a supplier. Below is a brief discussion of the important facts about mezzanines.

Framing

Framing is crucial for proper support of the mezzanine. Some of the types of framing include:

C-Section

C section spans an innumerable number of anxiety and accept no limit to the size and type of application where it can be used.

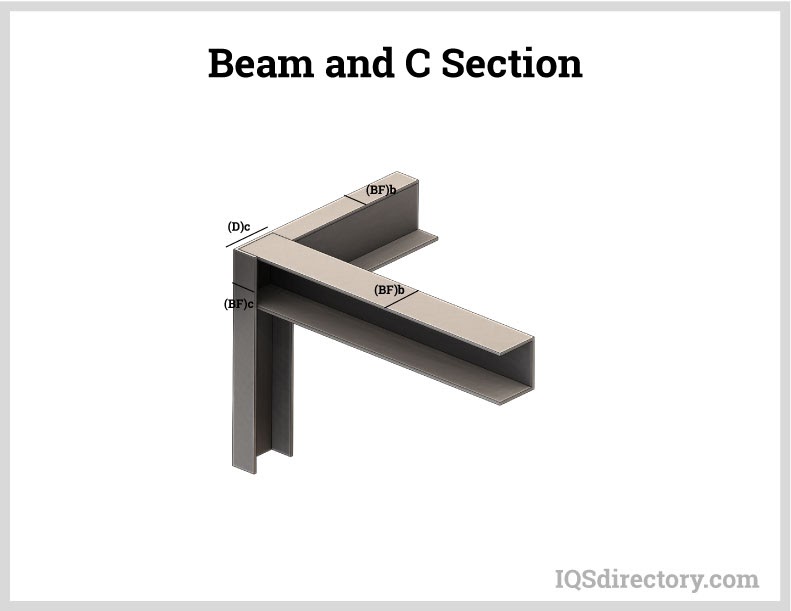

Beam and C-Section

Beam and C-Section can span more than than 20 feet in i direction and keeps the depth of construction to a minimum. The combination is used in all sizes of mezzanines.

Beam and Beam

Beam and Beam is used for heavy loading or unusual spans.

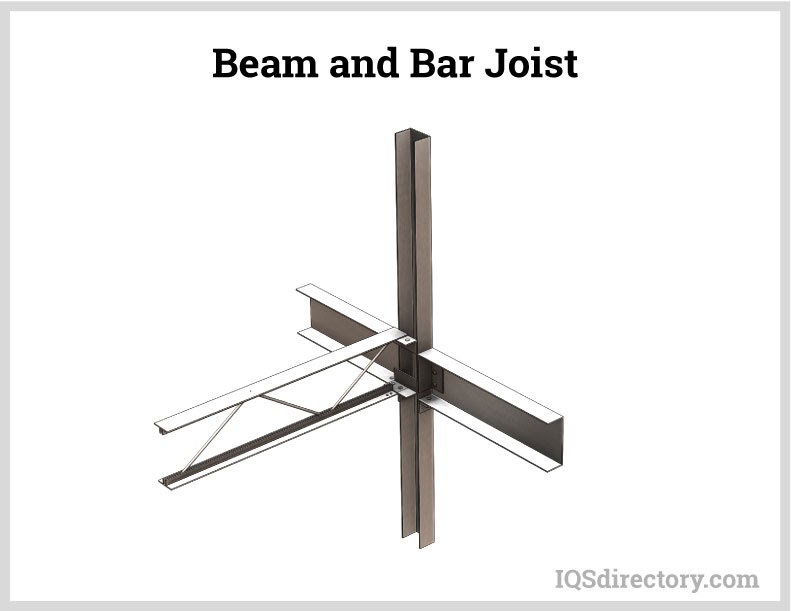

Beam and Bar Joist

Beam and Bar Joist is used for medium to large mezzanine projects where wide spans and high capacity are needed.

Bar Joist and Girder Joist

Bar Joist and Girder Joist are open-web and are used in large projects or in big spans where high capacity is needed.

Handrails and Guardrails

Handrails are on stairways and must be 36″ high from the stair tread. They must be welded and have a smooth and continuous end.

A guardrail prevents a person from falling over the edge and must exist a minimum of 42″ high.

Pounds Per Square Foot

PSF determines the design load or uniform load from Table 1607.1 of the IBC Code. The minimum design load for mezzanines or work platforms is 125 PSF. Very few applications require a uniform load heavier than 125 PSF. A fifty′ x 50′ mezzanine, with a 125 PSF, can handle 312,500 pounds, which is 208 pallets weighing i,500 lbs. The PSF for a mezzanine is the boilerplate for the whole deck of the mezzanine and not one specific spot.

Footings

Footings may exist necessary if it is adamant that the building's slab will not exist able to handle the load. The decision for using footings is from the design engineer who checks the original blueprints of the edifice.

Stair Runs

Each coding agency has a different method for determining stair runs.

- OSHA Stairs - A horizontal run should be equal to the deck acme.

- IBC - A stairs horizontal run should be ane-1/2 times the deck superlative. Stairways with a deck acme above 12' must take intermediate landings, which must be factored into the horizontal run.

Structural Materials

Steel, stainless steel, aluminum, and fiberglass are usually used in the construction of mezzanines.

- Aluminum – is rust resistant and tin can be washed and cleaned regularly. It is very light and used for smaller mobile platforms.

- Fiberglass – like aluminum, does not rust and can be cleaned oft. Fiberglass has a shine end without chips or burrs.

- Cold rolled steel – has smooth surfaces and can be used in display applications or public buildings. It is pre-galvanized, which makes it less expensive than hot rolled steel, stainless steel, or aluminum.

- Structural steel – tin can have greater column spacing. Electrical conduit or h2o pipes tin be installed through its joist. Structural steel mezzanines are heavier and have a higher expressionless and floor load. The surfaces on structural steel mezzanines are rough and coarse.

- Stainless steel – is resistant to moisture and chemicals and FDA approved. Stainless steel mezzanines are designed for easy cleaning and are used in food processing plants.

Chapter Seven – Building Codes for Mezzanines

Building codes are the basic rules for deciding if a mezzanine is an intermediate level or another floor of a building. The main regulating agencies are the International Building Code (IBC) and the Occupational Safety and Wellness Assistants (OSHA). They have very similar definitions of what a mezzanine is.

The International Building Code definition of a mezzanine is:

"A mezzanine is an intermediate level between the floor and ceiling of whatsoever story. In regards to the building lawmaking, mezzanines must comply in accordance with Section 505.2 of the International Building Code (IBC)."

A mezzanine, in compliance with Section 505.two, is considered a portion of the story in a higher place and does not demand to contribute to the building area or number of stories as stipulated in Department 503.one, when determining the size of a building. Though it is not factored into the building area, its square footage will be included in determining the fire area. Mezzanines must be constructed of materials documented to the building's Construction Type per Tabular array 601.

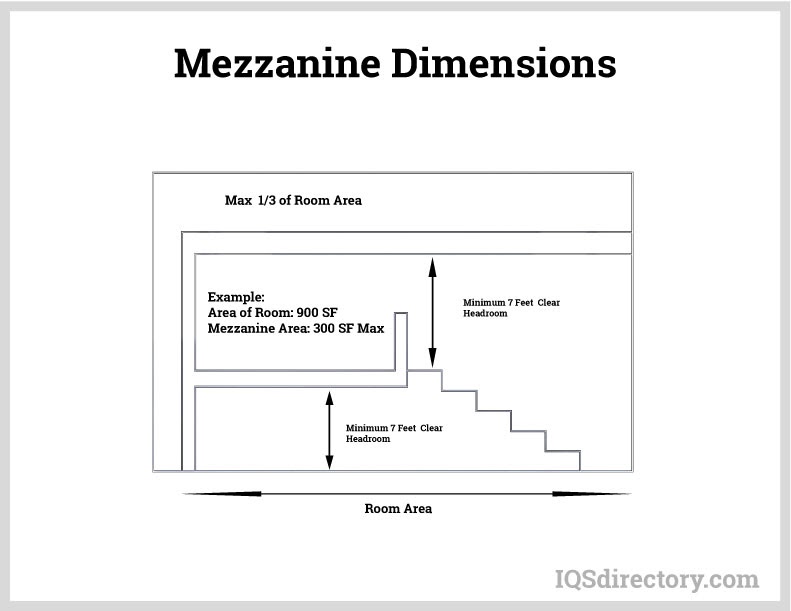

505.2.ane Mezzanine Expanse Limitation

The clearance acme to a higher place and below a mezzanine cannot be less than vii feet. The total area of a mezzanine, within a room, cannot exist greater than 1/iii the floor area of the room in which it is located.

505.2.2 Means of Egress for Mezzanines (Exiting)

Occupants of a mezzanine must have access to at least two means of egress where the common path of egress traveled exceeds the limitations of Section 1014.iii. Where a stairway provides a means of exit access from a mezzanine, the maximum travel distance includes the distance traveled on the stairway measured in the plane of the tread nosing. Accessible means of egress shall exist provided in accordance with Section 1007.

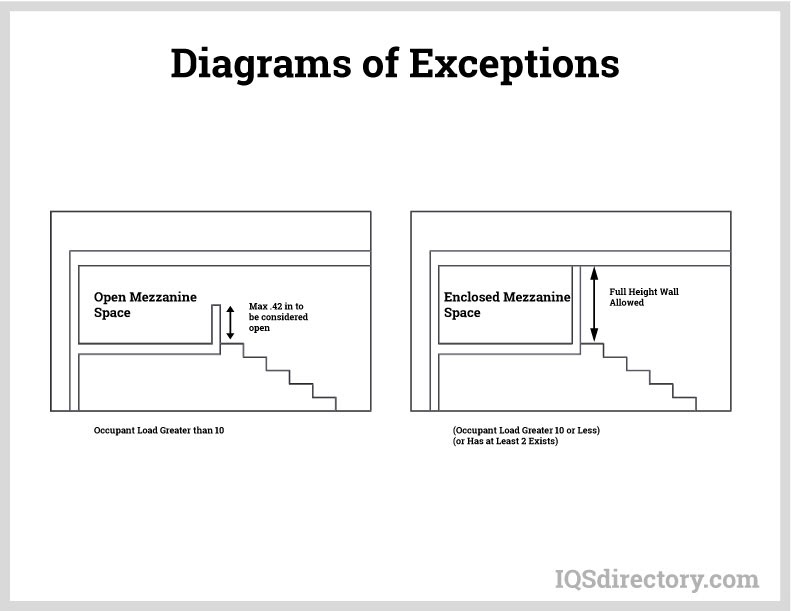

505.2.three Mezzanine Openness

A mezzanine must exist open to the room in which it is located, except for walls that are not more than 42 inches in acme. At that place are exceptions to the openness rule. 1 exception is if there are not more than ten people on the mezzanine. Some other exception is if in that location are 2 or more exits.

Other IBC Regulations

- 505.5 Equipment Platforms

- 505.v.1 Area Limitations

- 505.five.two Burn down Suppression

- 505.5.3 Guards

OSHA Regulations

OSHA's regulations for mezzanines autumn under construction standards for fall protection titled Walking Working Surfaces Rule, 1910 Subpart D:

- Duty to Have Fall Protection

- Fall Protection Systems Criteria and Practices

- Guardrail Systems-Not-mandatory Guidelines for Complying with 1926.502(b).

Conclusion

- A mezzanine is an intermediate floor installed in a building betwixt the main floor and the ceiling that is partly open to the master floor.

- Mezzanines can be permanent or temporary and tin serve as actress office infinite, storage area, or a work platform.

- There are several forms of mezzanines that are designed to fit specific conditions.

- Mezzanines can be used for office space, an extra work area, storage, or a platform for equipment employ.

- The regulations regarding the installation of a mezzanine are determined by the IBC and OSHA.

- When planning to install mezzanine, it is of import to be sure that the building floor tin can handle the extra weight.

GET YOUR Visitor LISTED BELOW

Leading Manufacturers and Suppliers

Source: https://www.iqsdirectory.com/articles/mezzanine.html

Posted by: heathyouds1976.blogspot.com

0 Response to "How To Install A Mezzanine Floor"

Post a Comment